Choosing the Right Industrial Touch Monitor

Industrial environments demand robust and reliable touch monitors to meet the unique challenges of heavy-duty applications. Selecting the right industrial touch monitor is crucial for ensuring optimal performance, longevity, and compatibility with specific operational requirements.

Origin and Considerations

The quest for the ideal industrial touch monitor arises from the need to balance durability, functionality, and cost-effectiveness in demanding industrial settings. Unlike consumer-grade displays, industrial touch monitors must withstand harsh conditions such as extreme temperatures, moisture, dust, and vibrations while delivering consistent performance.

Key considerations in choosing the right industrial touch monitor include:

Durability: Industrial touch monitors should feature rugged construction and protective enclosures to withstand physical impacts and environmental hazards commonly encountered in industrial environments.

Compatibility: Compatibility with existing hardware and software systems is essential for seamless integration and interoperability, minimizing downtime and optimizing productivity.

Touch Technology: Various touch technologies, such as resistive, capacitive, and infrared, offer distinct advantages in terms of sensitivity, accuracy, and resilience to environmental factors.

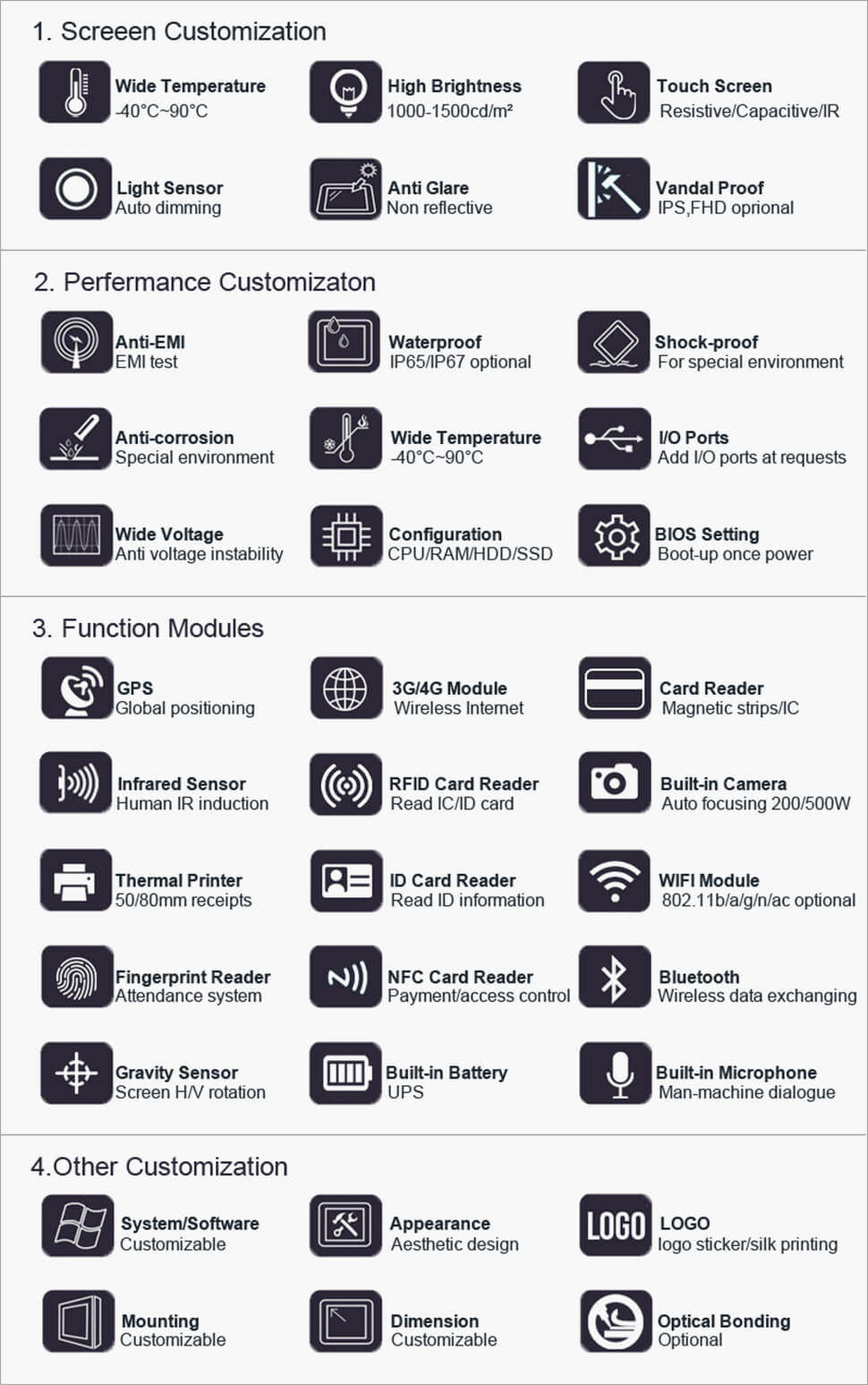

Customization Options: The ability to customize industrial touch monitors according to specific requirements allows for tailored solutions that address unique operational needs and preferences.

Validation and Performance

The efficacy of industrial touch monitors is validated through rigorous testing and certification processes, ensuring compliance with industry standards and regulatory requirements. Manufacturers subject their products to comprehensive performance assessments, including reliability testing, environmental stress testing, and electromagnetic compatibility testing, to guarantee reliability and performance in real-world industrial scenarios.

Furthermore, user feedback and case studies provide valuable insights into the practical performance and usability of industrial touch monitors across diverse applications and industries. Positive testimonials and documented success stories underscore the tangible benefits of choosing the right monitor for specific industrial applications, ranging from manufacturing and automation to transportation and logistics.

Significance and Impact

The significance of choosing the right industrial touch monitor extends beyond operational efficiency to encompass safety, reliability, and cost savings. A well-selected monitor enhances operator visibility, facilitates intuitive interaction with machinery and control systems, and reduces the risk of errors and accidents in industrial settings.

Moreover, customized industrial touch monitors empower organizations to optimize workflow processes, improve decision-making, and achieve competitive advantages in rapidly evolving markets. By investing in tailored solutions that address their unique needs and challenges, industrial enterprises can future-proof their operations and capitalize on emerging opportunities for innovation and growth.

In conclusion, the process of choosing the right industrial touch monitor is a critical aspect of industrial automation and digital transformation initiatives. By prioritizing durability, compatibility, and customization, organizations can deploy robust and reliable touch screen solutions that enhance productivity, safety, and competitiveness in the industrial landscape.

For meeting diversified requirements of customers and providing personalized service , we established a specialized team of customization, specialize in making customized products to meet customers' requirements. OEM & ODM is warmly welcomed, customization is our specialty, provide fast and cost-effective sample, and support both small order and mass customization.